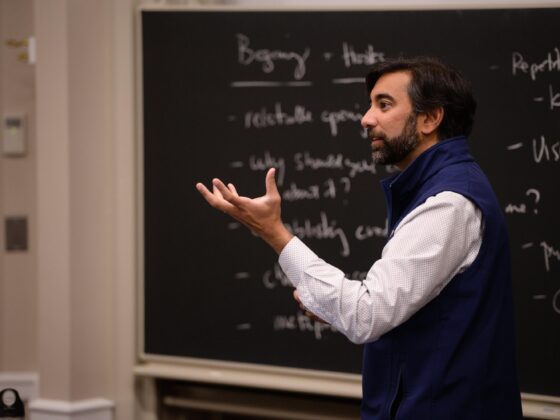

Professor Elliott Weiss is an expert with extensive consulting experience in manufacturing, project management,

lean systems, logistics and workflow management. He recently provided insights on ways business can take a few pointers from basketball great Steph Curry, On The (Basket)ball: What Business Can Learn From Steph Curry.

From Ideas to Action:

The Warriors’ point guard goes to extreme lengths to improve the odds that any given basketball he shoots will swish through the net. This embraces the concept of continuous process improvement, says Darden Professor Elliott Weiss. “I teach and write on continuous process improvement, the relentless pursuit of creating value,” says Weiss. “We see Curry practicing this, trying relentlessly to improve.

Pioneered by Japanese automotive firm Toyota, continuous process improvement (CPI, or kaizen) focuses specifically on reducing variability to create superior products, says Weiss. Curry has been doing the same, practicing with a special motion-sensing technology that tells him exactly how far off-center each shot is. As the ball reaches the rim, a voice calls out a number from -9 to 9 to tell him how many inches from dead center it is, with 0 being a perfect swish. Even when a ball makes it through the hoop, Curry can tell when it is less than perfect and adjust his shot to make it better.

Read the full article here.